Cooler series

Radiator series

Unpowered dryer

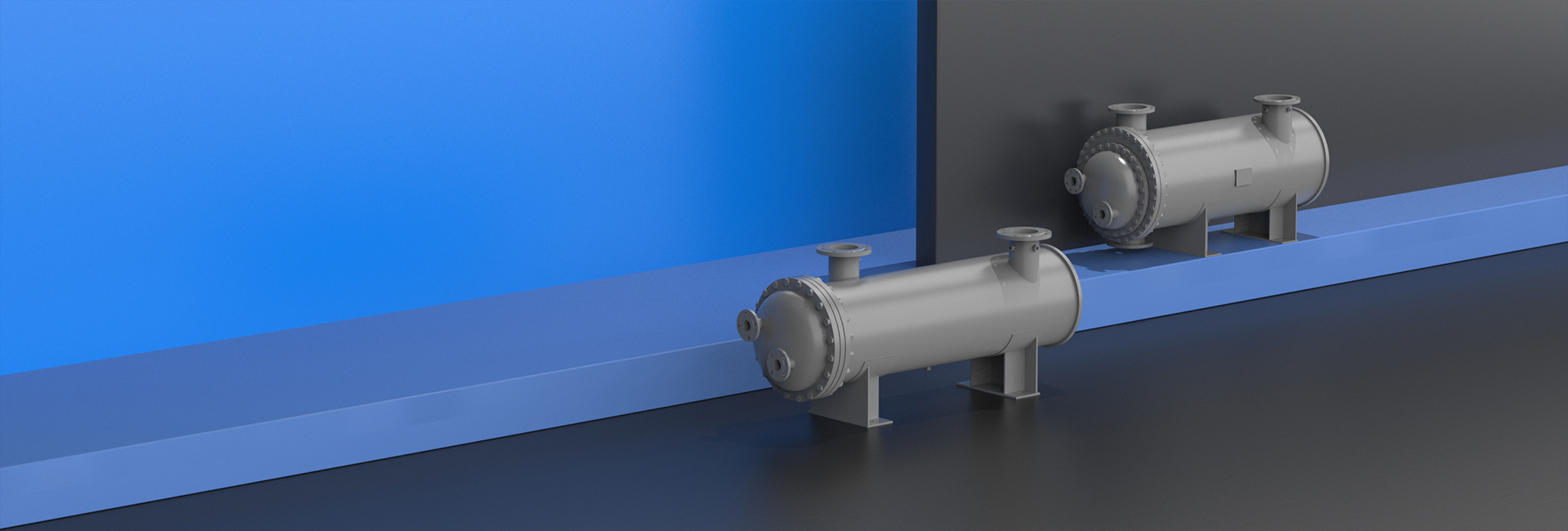

Pressure vessel series

Waste heat recovery series

100 Cubic waste heat recovery device

+86 18168346028

+86 17353555541

Joel15007@outlook.com

Monday to Saturday 8:00-17:00

Product Introduction

Waste heat recovery device is an energy recovery equipment that can recover and utilize the waste heat generated in industrial production processes. By using specific technical means such as heat exchangers and thermoelectric converters, the heat in the exhaust gas is collected and converted into useful energy sources such as thermal or electrical energy. This can not only improve energy efficiency and reduce energy consumption, but also help reduce carbon emissions and meet environmental requirements. This product is widely used in the chemical industry: in chemical processes such as refining, refining, synthesis, etc., high-temperature exhaust gas and waste heat are often generated. The waste heat recovery device can convert these exhaust gases and waste heat into heat energy or steam, which can be used to meet the heating needs of chemical processes and improve energy utilization efficiency.

It has the following advantages:

1. Short investment return cycle: Usually, the investment cost can be recovered within one to three years.

2. Environmental protection and energy conservation: It has a positive effect on environmental protection and complies with national energy policies and environmental requirements.

It has the following advantages:

1. Short investment return cycle: Usually, the investment cost can be recovered within one to three years.

2. Environmental protection and energy conservation: It has a positive effect on environmental protection and complies with national energy policies and environmental requirements.